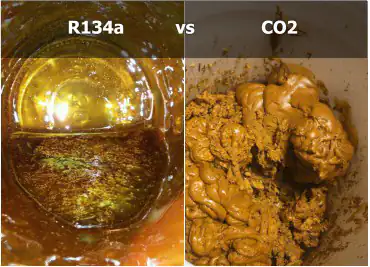

One other method of hemp extraction is using a tetrafluoroethane (TFE) R134a as a solvent. R134a by itself is often used in aerosol products for drug delivery. Products that are extracted using this method are called post winterized full spectrum oils as the amount of waxes in the extract right off the machine is usually less than 5%. The process is very similar to CO2 extraction due to the fact that both are utilizing a gas for extraction and liquefying it when it is in contact with the material.

The extraction with R134a is performed at low pressure and room temperatures to strip the natural oils from the raw hemp products in a closed loop system. The gas is slightly pressurized, then driven through the plant material and recovered in a separation tank leaving the full spectrum oil behind. R134a is safe for human health – Nontoxic, FDA approved and qualified it as GRAS (Generally Recognized As Safe). European Union approved the usage of the gas as solvent by EC Directive 2009/32.

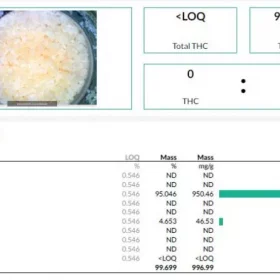

The small non-polar molecule size and the inert nature of the R134a solvent penetrates the plant tissue extremely well and extracts thoroughly the oil-soluble fractions. R134a extraction is performed at room temperature conditions and the extraction process is neutral to the plant full spectrum oil. The full terpene profile is collected without degradation of components and it is easily separated from the solvent. That is why the extraction is very often done on fresh plants as well. R134a does not extract solids and in most cases, winterization is not required. Furthermore, it does not transfer water-soluble compounds as chlorofil, mould or some pesticides in the extract. That makes R134a a very pure process for extracting plant oils. This process called Pure Botanical Extracts (PBXTM) has been pioneered by COMERGTM who owns the worldwide IP and know-how of the R134a extraction technology.

One of the most popular methods of hemp extraction is via CO2 as a solvent. This method uses the advantage of the supercritical properties of CO2 gas to strip materials from botanical substances. This method for extraction has been used by a variety of industries before it was applied to hemp, like perfumes and essential oils. Although the cannabinoids have quite different structure than the essential oils and they cannot be extracted together. That is why extracting the hemp oils with CO2 is by running supercritical extraction and the terpenes by running subcritical extraction which makes the process quite long. CO2 is a low dense gas and needs to be pressurized to about 600 atmosferes to become a solvent for those tick oils. That is why due to the process architecture scaling the CO2 system and operation is an expensive process.

CO2 extraction can not extract very well moist material as the moisture and CO2 connection brings up undesired acidity level in the extract. Unlike CO2, R134a is inert, odourless, non-toxic, non-flammable, non-corrosive and does not form an acid in the presence of moisture. This widens the scope of applications to include many pharmaceutical products that are pH-sensitive. It is very important to know that the room temperature of extraction means no thermal degradation or loss of volatile compounds during isolation. Low boiling point of R134a eliminates the need of complex and slow solvent recovery.

CO2 extraction requires special training and expensive equipment in contrast R134a is easy to operate from non-scientist with extremely high consistency on the output oil. CO2 brings High CapEx as you may run several systems and an army of technicians, this is costly compared to R134a with very low cost of maintenance and workforce. “We have been consistently looking in the use of alternative safer and better solvents for extracting plant derived resins for quite some time. A good chemist knowing the properties of the target materials to be extracted and understanding the solvent selectivity would understand the value.”, said the CEO of COMERG Dr. George Stantchev.

COMERG makes Ethanol, Hexane, SHW and Steam extraction systems and the best way for extracting full spectrum plant resins with a complete terpene profile is none of the above. That is why we promote the systems with R134a for extraction of hemp. Although, knowing the solubility of all above solvents we often use co-solvents combinations for extracting and isolating other specific fractions beside oils as example, powder, resin and tinctures.

George Stantchev, CEO

george@comerg.com

(602) 992-0744