What is in the plant?

Cannabis oils also called terpenes are derived from the cannabis plant (cannabis sativa). It grows wild in many of the tropical and modest temperate areas of the world. It can be grown in almost any climate. Two main species may be recognized: Cannabis sativa and Cannabis indica. Cannabis sativa is a low-THC variety or subspecies of Cannabis which is native to Central and Eastern Europe and Russia. Cannabis indica produces large amounts of tetrahydrocannabinol (THC). The higher concentrations of THC provide euphoric and intoxicating effects making it popular for use both as a recreational and medicinal drug. That strain takes its name from the Hindu-Kush Mountain range where it has been originally discovered. Because of the often harsh and variable (extremely cold winters, and warm summers) climate of those parts, C. indica is well-suited for cultivation in temperate climates.

Cannabis oils also called terpenes are derived from the cannabis plant (cannabis sativa). It grows wild in many of the tropical and modest temperate areas of the world. It can be grown in almost any climate. Two main species may be recognized: Cannabis sativa and Cannabis indica. Cannabis sativa is a low-THC variety or subspecies of Cannabis which is native to Central and Eastern Europe and Russia. Cannabis indica produces large amounts of tetrahydrocannabinol (THC). The higher concentrations of THC provide euphoric and intoxicating effects making it popular for use both as a recreational and medicinal drug. That strain takes its name from the Hindu-Kush Mountain range where it has been originally discovered. Because of the often harsh and variable (extremely cold winters, and warm summers) climate of those parts, C. indica is well-suited for cultivation in temperate climates.

The “Entourage effect”

The phrase entourage effect was introduced in 1999. It is a novel method of endocannabinoid regulation by which multiple endogenous chemical species display a cooperative effect in eliciting a cellular response, the term has evolved to describe the polypharmacy effects of combined cannabis phytochemicals or whole plant extracts. The phrase now commonly refers to the compounds present in cannabis supposedly working in concert to create “the sum of all the parts that leads to the magic or power of cannabis”.

There are more than 75 known cannabinoids that occur in the cannabis plant. Each of them have specific functions in stimulating certain cells. As example CBD stimulates the collagen, CBG stimulates the stem cells, THCV stimulates the peripheral nervous system, THC stimulates the central nervous system, etc. Other cannabinoids, terpenoids, and flavonoids may be part of an entourage effect. The entourage effect is considered a possible cannabinoid system modulator and is achieved in pain management

Consider the role of terpenes, for example. Terpenes are volatile aromatic molecules that evaporate easily and readily announce themselves to the nose. Various researchers have emphasized the pharmacological importance of terpenes, or terpenoids, which form the basis of aromatherapy, a popular holistic healing modality. Marijuana’s compelling fragrance and particular psychoactive flavor are determined by the predominant terpenes in a strain.

There are over 3000 terpenes in the world and 400 of them have been found in cannabis and 70 of them are identified as cannabinoids, but only a few of these odiferous oily substances appear in amounts substantial enough to be nose worthy. Among them are monoterpenes, diterpenes, and sesquiterpenes, which are characterized by the number of repeating units of a 5-carbon molecule called isoprene, the structural hallmark of all terpenoid compounds.

The terpenes in marijuana have given the plant an enduring, evolutionary advantage. The terpenes are the natural hormones of the plant. During the vegetation of the plant the terpenes change from repelling insects and animal grazers, preventing fungus and attracting pollinators from male plant pollination. That is why used in proper combinations the terpenes can elevate human emotions as well and in addition they modulate the performance of the cannabinoids.

Extracting the oils

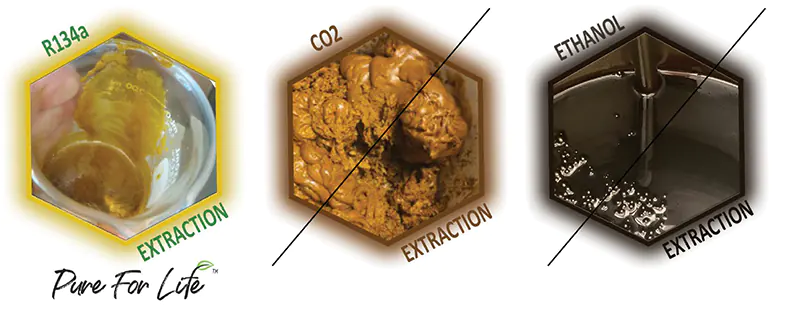

Different forms of extraction methods used to concentrate and target molecules from plants have been around for centuries. Cannabis extraction processes have adapted different techniques popularly used in today’s agriculture, biopharma and petrochemical industries. There are few most commonly used extraction methods used in the creation of cannabis crude oil: CO2, hydrocarbon and ethanol. Each of these methods have their own set of pros and cons, as outlined in detail below.

CO2

One of the most popular methods of cannabis extraction is via CO2 as a solvent. This method uses the advantage of the supercritical properties of CO2 gas to strip materials from botanical substances. This method for extraction has been used by a variety of industries before it was applied to cannabis, like perfumes and essential oils. Although the cannabinoids have quite different structure than the essential oils and they cannot be extracted together. That is why extracting the cannabis oils with CO2 is by running supercritical extraction and the terpenes by running subcritical extraction which makes the process quite long. CO2 is a low dense gas and needs to be pressurized to about 600 atmospheres to become a solvent for those thicker oils. That is why due to the process architecture scaling the CO2 system and operation is an expensive process. Using CO2 requires post extraction lipid and wax separation by use of lipophilic solvent as ethanol which adds additional cost and time to the process.

Hydrocarbon

Hydrocarbon extraction is a method that uses a hydrocarbon as a solvent, such as butane or propane, washed over the plant matter, to ultimately concentrate a targeted, desired molecule and remove it from the biomass. Hydrocarbon extraction has become popular due to its efficiency in the areas where CO2 falls short. It has a higher yield rate, preserves different terpenes than other methods and equipment is merely affordable. Although the solvent boiling point is still high enough to require solvent vacuum purging and remediation.

Overall, this method of extraction shows good yield, but also comes with its own set of drawbacks. Chemicals like butane are volatile gases and obviously have a high potential for combustion and flammability, resulting in zoning and storage limitation laws put in place for safety purposes. Consequently, this creates limitations on scalability for operations locking to expand. If a manufacturer is looking to scale, hydrocarbon extraction is not advised. Also de-waxing during a hydrocarbon extraction is an issue and secondary solvent dewax will need to be performed in order to remove any stray lipids that made their way into the oil during extraction.

Ethanol

Ethanol is now the preferred method by most hemp extractors because it is simple and scalable. The real advantage to this method is its ability to effectively scale up within manufacturing operations. Especially after the extraction has been done with cold ethanol below -40C and the benefits of limited chlorophyll and wax extraction are even more. Winterization uses ethanol and sub-zero temperatures to separate unwanted fats and waxes from the oil. That is why the oil extracted this way is with minimal fats and lipids and looks like post winterized crude. The major disadvantage of ethanol is that it denatures the oil.

Another disadvantage of ethanol is the high boiling point of around 80 degree C. That means that in order ethanol to be separated from the extract the temperature may exceed 100 degree C. Also the lowest boiling point of the terpenes is 119 degree C which means that the ethanol-water solution will be already contaminated with terpenes and will need to be purified very often. Such a process brings loss of solvent at around 15-20% extractor volume at every run which increases the operational cost of the extraction significantly especially when in scale.

New trends

So far we have seen that almost any common method of extraction is either running at higher pressure and temperature to allow the solvent to extract or has to be run at low temperatures to avoid drawing fats, lipids and chlorophylls. That creates additional obstacles such as decreasing yield, slowing the process and increasing the CapEx. In this article we are in a hunt for a better option that does not require putting the solvent in extreme conditions to extract our target components by utilizing alternative processes that can be performed at room temperature and preserve all plant values.

From what we have seen, all popular methods used in cannabis extraction have their advantages and disadvantages. The most common for all of them is that they gravitate around the extraction of cannabinoids most oftenly calling the cannabinoid mixture a full spectrum oil while not really valuing the presence of the rest of the terpenes. Our objective in this paper is to analyze all options from simplicity, safety and consistency to deliver full spectrum resin containing all medical values at lowest cost.

R134a terpene wash

One other method of cannabis extraction is using tetrafluoroethane (TFE) R134a as a solvent. R134a by itself is often used in aerosol products for drug delivery. Products that are extracted using this method are called post winterized full spectrum oils as the amount of waxes in the extract right off the machine is minimal. The process is very similar to CO2 extraction due to the fact that both are utilizing a gas for extraction and liquefying it when it is in contact with the material.

The extraction with R134a is performed at room temperatures and is able to strip the natural oils from the raw cannabis products in a closed loop system. The gas is slightly pressurized, then driven through the plant material and recovered in a separation tank leaving the full spectrum oil behind. R134a is safe for human health – Nontoxic, FDA approved and qualified it as GRAS (Generally Recognized As Safe). European Union approved the usage of the gas as a solvent by EC Directive 2009/32.

R134a extraction is the method PURE5 Extraction by COMERG has pioneered after many years of diligent research and prototyping. PURE5 has effectively isolated R134a to be the most appropriate method of primary plant matter extraction. As a primary extraction it just draws the terpenes and the heavier resins out, in our case – the cannabinoids. In COMERG we have applied this method on over 150 various herbs before we applied it to the cannabis industry.

COMERG builds ethanol, SHW and steam distillation equipment but utilizing the R134a extraction solvent in the cannabis industry is the prefered extraction, because it is simple, safe and scalable.

RURE5 is now leading the commercial scale extraction by size and speed, currently there are systems available for up to 8000lb/day. PURE5 is paving the way for R134a as a sustainable solution for the production of full spectrum crude cannabis oil.

Dual-solvent wash

A great addition to the use of R134a is the use of ethanol as a sequential extraction solvent. The best way to preserve terpenes and more volatile cannabinoids is to extract with R134a. This is a very quick extraction during which all terpenes and cannabinoids can be collected in a live resin. That extraction followed by a secondary cold ethanol extraction would extract only the remaining cannabinoids in a very high concentration and will skip the distillation process.

The PURE5 dual system overcomes the ethanol and CO2 disadvantages above. In this case the non polar solvent extracts all volatile substances like terpenes and the secondary polar solvent – all cannabinoids. During that process the residual water is removed at the R134a extraction stage as well as all terpenes, the cold ethanol is not going to be contaminated with low temperature volatile substances and when recovered in our close loop system the loss is significantly less.

Knowing your solvent

Selectivity

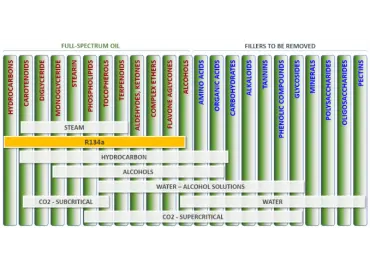

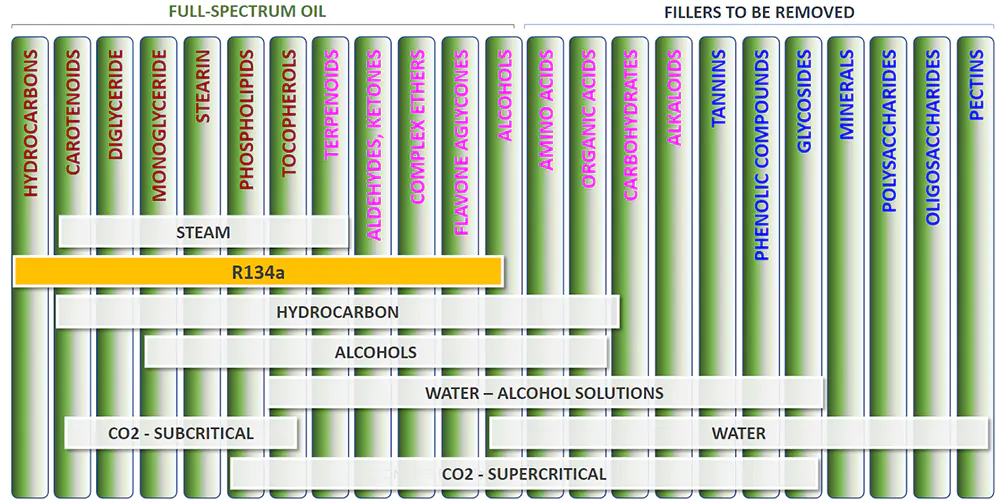

When looking at starting an extraction operation, one should consider each of the extraction methods available as part of their overall operation and decide what is best for its operational expense. The foundation of extraction is knowing your solvent and what botanical components it will draw from the plant. That will answer your other question about how many post processing activities you need to do and respectively how much money you need to spend on equipment and personnel.

It is very important for the extraction artist to understand what end product each solvent will provide him. There are few clues on how to recognize the effect of one solvent versus another. First one is to compare the solvent by molecule polarity. It has been known that the polar solvents extract much wider regions of the plant botanicals and the solvent with non polar molecules will extract more volatile components, such as terpenes and cannabinoids.

Because polarity is a very wide topic and the solvent behavior is not consistent and changes depending on temperature, pressure and purity, another way to determine the solvent properties is to compare the solvents by dielectric constant. It has been known that the dielectric constant of water is around 80, ethanol around 25, R134a around 7, etc. Those constant changes depending on temperature as example water dielectric constant changes between 90-30 between 0 to 300 degree F. In the diagram below the various solvent behavior was shown illustrated toward the botanical substances dissolved.

In the figure above are shown the range of organic substances each solvent draws from the plant matter depends on the polarity. The right solvent is of major importance for extraction of the TRUE full spectrum resin. There are oil soluble compounds (red), alcohol soluble compounds (pink) and water soluble compounds (blue) in the plants, that is why it is important to select your solvent base in regards to what compound to be extracted.

When you extract essential oils you use solvents with dielectric constant less than 15, extracting alcohol soluble use solvents with dielectric constant of 15 – 50 and extracting water soluble over 50. Use of steam or CO2 has never been an efficient method for extraction of terpenes. Extractions with R134a is the best way to preserve all the terpenes as they exist in the plant without additional post processing and chemicals treatment.

While CO2 and hydrocarbon extraction methods both produce acceptable results in the creation of cannabis concentrates, the post-processing and filtration requirements during the dewaxing or winterization processes create issues for commercial producers when attempting to scale their operations up.

Terpenes

Due to the exceptional performance of R134a with terpenes we have created a Pure Botanical Extraction (PBXTM) process to deliver the highest concentration of terpenes. The PBXTM extraction process employs a room-temperature, non-polar fluorocarbon solvent allowing us to capture every potential terpene along with elemenes & ketones all suspended in the natural oils from the hemp flowers.

What is unique, is that the extracted terpene profile repeats the exact terpene profile from the flower in approximately 30 times more concentrated form. Since the extraction is carried out at room temperature there is no destruction of existing terpenes or new by-products created in the process. That means that the experience of using the flower in any delivery form either vape, supplement or topical will be exactly as the plant itself maintains the terpene, enzimatic and mineral content intact.

Myrcene, caryophyllene, humulene, pinene and linalool are more common amongst hemp flowers however the quantity present in Lifter makes this a very complex flower profile yielding superior entourage effects.

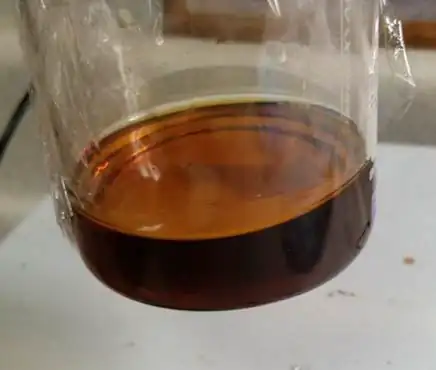

Live Resin

The Live Resin is the most unaltered form of the cannabis oil where all constituents are extracted as they occur in the plant at room temperature and all terpenes are collected without degradation caused by the processing. Typical use is intake as a medicinal supplement and vaping. A concentrate is activated full spectrum oil with concentration at around 70-80% used in preparation of supplements.

The true health values of the plant are in the terpene profile combined with cannabinoids and concentration 1:10 to 1:30 from the original plant. Concentrates and distillates are presently dominating the market due to the lack of a single step low cost process for obtaining the resin without the solids. PURE5 obtains its live resin through a single-step extraction leveraging use of GRAS solvent that does not draw the chlorophylls.

Economics

The cannabis field becomes more and more competitive every day. Extract quality, clarity, cost and time to market becoming very essential. The margin is not great enough anymore to drain your ethanol solvent in the sink when contaminated or to hire 10 people to do post processing. Step by step the operation starts to look like a white room where clean is the king. With that said the energy consumption and the ongoing maintenance will be key components to consider. This is usually information the vendors avoid to discuss.

Energy

The PURE5 20L system uses 4kW max power to operate and the 200L system uses 30kW max power to operate. That means that we use around 125W/liter to extract or around 350Wh to extract a pound of material. Other words it cost pennies to extract a pound of material. Considering the full automation and low maintenance of our machines and complete solvent recovery in a closed loop system, the overall cost to extract a pound with labor and utility will be well below a dollar.

Process

The process of extraction with R134a is by continuously washing the material with fresh solvent. During that time the material has been agitating and the solvent mixture is monitored for extracted plant matter. The material is fed by vacuum to the extractor and offloaded by vacuum which makes the loading and unloading process continues, fully automated and dust free. The system is built by the pharma regulations with 2 sections that are installed according to the process layout considering a clean room processing.

Who we are

PURE5 Extraction powered by COMERG is the most innovative extraction company, we design and manufacture cost and process optimized extraction systems and applicable post processing stages targeting specific end products. COMERG is committed to offer the fastest, safest and most economical extraction process for CBD/THC oils named Pure Botanical Extraction (PBXTM) standard.

COMERG originates its roots from building machines for the fragrance and flavor production in Europe. This technology alone and with the combination of Ethanol have been used in extraction of various herbs. The consistency and the economics have been proved over a couple of decades. Based on that vast experience COMERG developed a few levels of equipment by processing capacity.

TF2L010AU Lab unit

The TF2L010AU machine processes 40lb of material a day. It is fully automated and the most reliable machine out there. Consuming 2kW on average and not requiring expert installation and operation this is the most user friendly and safe extraction equipment in the industry providing on average around 1-2kg extract a day that can be directly infused in a product. It has been widely used by the industry for direct formulations.

TF2L100AU Extraction area

The TF2L100AU machine extractors are installed separately from the skid. Also the loading and unloading is done by vacuuming the material and collecting it in the cyclone in order to maintain very low dust levels. While this machine supports high production loads it is extremely easy to operate and maintain.

Extractors are manufactured with 304 stainless steel with volume of 100L that can accommodate 15-20kg raw material and the entire space needed for installation is around 50m2. Extractors are equipped with agitators and a vacuum system for load and offload. Extractors can be serviced through a bay flange. System is fully automated, remote controlled and installed as a full turnkey loaded with solvent.

TF2L100AU Clean Room area

The TF2L100AU machine processes 600lb of material a day. It is a fully automated and fastest production machine out there. Consuming 25kW on average installed as a turn key with close loop solvent recovery and not requiring expert operation this is the safest extraction equipment in the industry providing on average around 20-30kg extract a day that can be used directly in a product. As a GMP compliant system has been widely used by the medical cannabis and hemp industry for single pass processing.

Typical Install in GMP facility

The TF2L250AU and TF2L500AU models are upscaled versions of the TF2L100AU. They process respectively 2,000 and 4,000lb/day material and are a great addition to any hemp processing facility. The systems are modular and can scale easily up to cover dynamically changing processing loads.

The TE1L1000AU dual solvent system processes 2,000-4,000lb of material a day. It is a fully automated and most agile production machine out there. Consuming 45kW on average installed as a turn key with close loop dual solvent recovery and not requiring expert operation this is the most agile extraction equipment in the industry as it adopts to the end product quickly providing on average around 100-200kg extract a day that can be used straight in a product. This system is GMP compliant and have been used by multiple industries.

PURE5 powered by COMERG is an industry leader with the first single pass resin extraction technology with easy scalability and high safety rating. Our extraction systems are one of the most technically advanced processing plants available due to this fact: the client’s biggest advantage comes from cost, quality, experience, service, and lines of scalable equipment.PURE5 brings proven, scalable equipment, technological advances and years of acquired knowledge to any commercial processor, no matter the size of their operation.

Call us at 602-992-0744 or e-mail at info@comerg.com.